At BHT Forge, our machine shop operates as a dynamic hub of advanced forging and machining processes, combining modern manufacturing technology with skilled expertise. Our real-world operations focus on precision, consistency, and quality, ensuring reliable forged components that meet stringent industry standards and customer requirements.

CNC Machining

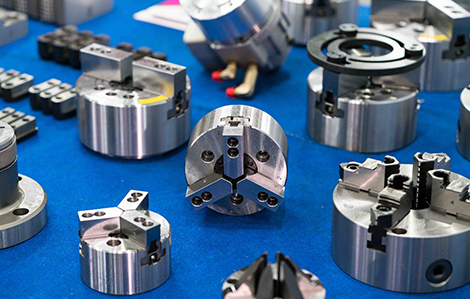

- Our CNC (Computer Numerical Control) machines are programmed to perform complex operations with incredible precision and repeatability.

- These machines handle tasks such as turning, milling, and drilling, ensuring high-accuracy components with tight tolerances.

- CNC machining is ideal for producing intricate parts required in industries like automotive, aerospace, and agriculture.