- Vertical Machining Centers (VMCs) are utilized for milling, boring, and drilling operations.

- These machines deliver superior surface finishes and dimensional accuracy, making them indispensable for manufacturing high-performance components.

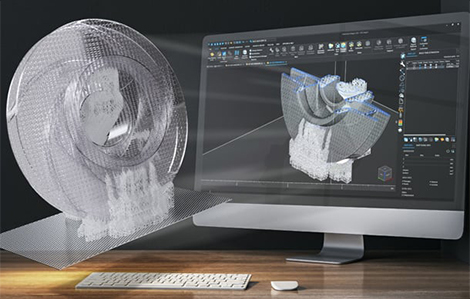

- The VMCs are equipped with advanced control systems for multi-axis machining, enabling us to produce complex parts with efficiency.