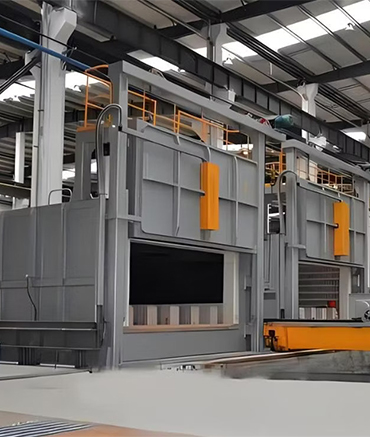

At BHT Forge, the tempering furnace plays a vital role in achieving the desired mechanical properties of forged components. Tempering is a controlled heat treatment process performed after hardening, where forged parts are reheated to a specific temperature below the material’s critical range. This step is essential to relieve internal stresses developed during forging and hardening, which could otherwise lead to brittleness or premature failure.

During the tempering process, components are heated uniformly and held at the target temperature for a defined period to allow the material structure to stabilize. This improves toughness, ductility, and impact resistance while maintaining the required hardness and strength. After the holding time, parts are cooled in a controlled manner to prevent distortion and ensure dimensional accuracy.

By precisely controlling temperature, holding time, and cooling conditions, the tempering furnace process at BHT Forge ensures consistent quality, enhanced durability, and reliable performance of forged components, making them suitable for demanding automotive, industrial, and engineering applications.